U.S. Patent Applications

How to Produce Packaging Supplies Effectively for Your Business?

In today's competitive market, the ability to effectively produce packaging supplies is crucial for businesses. Expert Johnathan Richards, a leader in the packaging industry, once said, "Quality packaging directly impacts customer perception." This highlights the vital role packaging plays in a brand's success.

Many businesses struggle to find the right balance between cost and quality. It's essential to choose materials that protect products and reflect brand values. The process of producing packaging supplies should also consider sustainability. In a world where eco-consciousness is growing, many companies face challenges in sourcing sustainable materials while remaining profitable.

Moreover, the efficiency of the production process is often overlooked. Many organizations find themselves caught in outdated practices. This can lead to delays and increased costs. Assessing current methods may reveal areas for improvement. Thus, focusing on streamlined processes can lead to both better quality and lower expenses.

Identify Your Packaging Requirements and Goals

Identifying your packaging requirements and goals is essential for your business's success. Start by analyzing what you need. Are your products fragile? Do they require temperature control? Each product type has its own needs. Take time to write these down. This simple step can guide your decisions.

Consider the end-user experience. How will customers open the packaging? Is it easy to dispose of? These details matter. If customers struggle, they may not return. Reflect on past experiences. Did your previous packaging meet expectations? If not, identify what went wrong. Learning from mistakes will improve your approach.

Budget constraints can also shape your goals. Beware of overspending on materials. Experiment with various options to find the best fit. Sometimes, cost-saving methods can lead to inefficiency. Measuring material effectiveness against your goals is crucial. Balance is key. A good choice today could enhance your brand tomorrow.

Research Suitable Materials and Suppliers

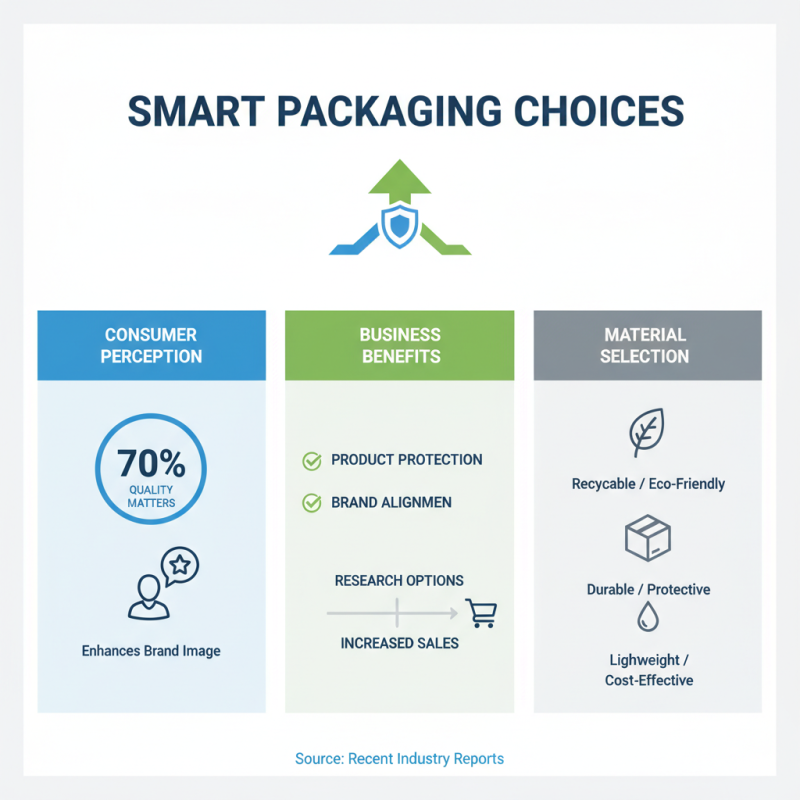

Selecting the right materials for packaging supplies is crucial for any business. Recent industry reports reveal that 70% of consumers consider packaging quality important. This means businesses need to invest time in researching various options. The right material not only enhances product protection but also aligns with brand values.

Finding reliable suppliers is another challenge. Statistics show that 60% of companies express difficulty in sourcing sustainable materials. Businesses often compromise on quality when under pressure to cut costs. However, this approach can lead to higher waste and customer dissatisfaction. It's essential to establish a strong relationship with suppliers who understand your needs.

Testing various materials before committing to production is also vital. Some materials may not perform as expected. For example, bioplastics can vary in durability. Early evaluations can save costs and prevent setbacks later. Being open to feedback from both your team and customers can guide improvements. 精益求精的态度将推动业务成功。

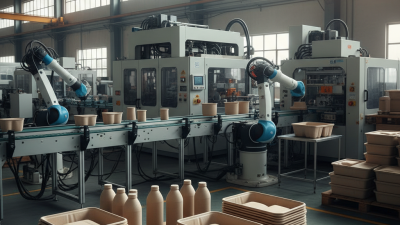

Evaluate Production Methods for Efficiency

When evaluating production methods for packaging supplies, efficiency is key. Begin by assessing your current production processes. Are they streamlined? Analyze the workflow to identify bottlenecks. Sometimes, small adjustments can lead to major improvements. For instance, consider machine upgrades that can speed up production without sacrificing quality.

Next, explore material options. Cheaper materials may reduce costs, but they could compromise product integrity. Look for suppliers that offer both affordability and durability. This balance is essential. Conducting trials with different materials can yield unexpected results. Measure the impact on both cost and time.

Also, be open to innovative techniques. Automation is trending, but it can be daunting to implement. Should you invest in automation? It’s worth weighing the potential long-term gains against initial costs. A less efficient method might be familiar but reevaluating it can lead to healthier profit margins. Don’t shy away from seeking feedback from your team. Their insights often illuminate aspects you might have overlooked.

Implement Quality Control Measures in Production

Quality control measures play a crucial role in the production of packaging supplies. These measures ensure that products meet specific standards and fulfill customer expectations. Implementing regular inspections during production can help identify defects early. It’s vital to establish checklists for different production stages. This can help teams monitor quality while reducing errors. However, it’s easy to overlook minor details, which can lead to significant issues later on.

Training staff on quality standards is essential. Workers must understand the importance of their role in maintaining quality. Encouraging them to report inconsistencies promotes a culture of accountability. Using visual guides can help in this process. Yet, even with training, human error can occur. Recognizing this, conducting random audits can provide additional reassurance. Addressing flaws should not be viewed as setbacks. Instead, they offer opportunities for improvement.

Lastly, customer feedback can serve as a valuable tool for quality control. Regularly reviewing customer experiences allows businesses to adapt packaging supplies to market needs. While relying on data is helpful, it’s crucial to remain open to change. Finding the right balance between efficiency and quality is challenging but necessary. In the end, businesses that prioritize these measures are better positioned for success.

Optimize Inventory Management for Packaging Supplies

Effective inventory management is essential for producing packaging supplies. According to a report from the Warehousing Association, 66% of businesses experience inventory issues. These problems can lead to delays and increased costs. Managing your stock efficiently helps mitigate these risks.

Optimize your inventory by keeping track of usage patterns. A study indicated that 30% of packaged supplies go unused at month’s end. Poor forecasting leads to overstocking and wasted resources. Implementing just-in-time (JIT) practices can help reduce excess inventory. JIT can lower storage costs and improve cash flow.

Consider utilizing inventory management software. This technology can automate tracking and improve accuracy. A survey showed that companies using such software saw a 25% increase in efficiency. Regularly review stock levels and supplier performance. This promotes a responsive supply chain and enhances operational efficiency. Mistakes can happen, and reassessing your strategies is crucial for continual improvement.

How to Produce Packaging Supplies Effectively for Your Business? - Optimize Inventory Management for Packaging Supplies

| Dimension | Details |

|---|---|

| Type of Packaging | Boxes, Pouches, Shrink Wrap |

| Material Used | Cardboard, Plastic, Biodegradable Materials |

| Average Cost per Unit | $0.50 - $1.50 |

| Lead Time for Production | 2 - 4 Weeks |

| Storage Requirements | Cool, dry place; Palleted storage |

| Inventory Turnover Rate | Monthly |

| Sustainability Practices | Recycled materials, Eco-friendly inks |